What Does Turbochargers Do?

Table of ContentsThe 8-Minute Rule for TurbochargersSome Known Details About Turbochargers Some Known Factual Statements About Turbochargers

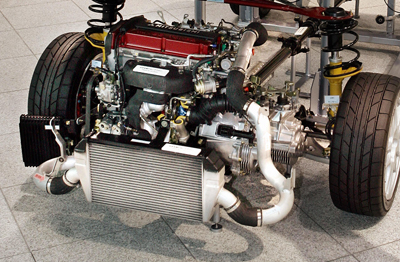

7 (in gas engines). The additional fuel is not burned (as there is insufficient oxygen to finish the chain reaction), instead it goes through a phase change from atomized (liquid) to gas. This phase change soaks up heat, and the added mass of the additional fuel decreases the average thermal energy of the charge and exhaust gas.A wastegate controls the exhaust gas circulation that enters the exhaust-side driving turbine and therefore the air consumption into the manifold and the degree of improving. It can be managed by an increase pressure helped, typically vacuum pipe accessory point diaphragm (for vacuum and positive pressure to return commonly oil infected waste to the emissions system) to force the spring-loaded diaphragm to stay closed until the overboost point is sensed by the ecu or a solenoid run by the engine's electronic control unit or a boost controller.

To avoid this from taking place, a valve is fitted between the turbocharger and inlet, which vents off the excess air pressure. These are called an anti-surge, diverter, bypass, turbo-relief valve, blow-off valve (BOV), or dispose valve. It is a pressure relief valve, and is generally run by the vacuum from the intake manifold.

The air is normally recycled back into the turbocharger inlet (diverter or bypass valves), however can also be vented to the atmosphere (blow off valve). Recycling back into the turbocharger inlet is needed on an engine that utilizes a mass-airflow fuel injection system, since disposing the excessive air overboard downstream of the mass airflow sensing unit causes an exceedingly rich fuel mixturebecause the mass-airflow sensor has actually already accounted for the additional air that is no longer being used.

More About Turbochargers

Turbocharging turbochargers can increase power output for a given capacity or increase fuel effectiveness by enabling a smaller sized displacement engine - turbochargers. The 'Engine of the year 2011' is an engine utilized in a Fiat 500 equipped with an MHI turbocharger. This engine lost 10% weight, saving up to 30% in fuel consumption while delivering the exact same peak horsepower (105) as a 1. Numerous Japanese companies produced turbocharged high-performance bikes in the early 1980s, such as the CX500 Turbo from Honda- a transversely mounted, liquid cooled V-Twin also offered in naturally aspirated form. Considering that then, few turbocharged motorcycles have been produced. This is partly due to an abundance of larger displacement, naturally aspirated engines being offered that offer the torque and power advantages of a smaller sized displacement engine with turbocharger, however do return more direct power qualities.

The very first turbocharged diesel truck was produced by (Swiss Maker Functions Saurer) in 1938 (turbochargers). A natural usage of the turbochargerand its earliest known use for any internal combustion engine, starting with experimental installations in the 1920sis with airplane engines. As an airplane climbs to higher altitudes the pressure of the surrounding air rapidly falls off.

Nevertheless, since the charge in the cylinders is pressed in by this air pressure, the engine typically produces only half-power at full throttle at this altitude. Pilots would like to benefit from the low drag at high altitudes to go much faster, but a naturally aspirated engine does not produce enough power at you could look here the very same elevation to do so.

As seen in the table listed below, there is considerable scope for forced induction to make up for lower density environments. A turbocharger treatments this issue by compressing the air back to sea-level pressures (turbo-normalizing), and even much higher (turbo-charging), in order to produce ranked power at high altitude. Because the size of click for info the turbocharger is picked to produce a provided quantity of pressure at high elevation, the turbocharger is extra-large for low altitude.

Early systems utilized a fixed wastegate, resulting in a turbocharger that worked much like a supercharger. Later systems utilized an adjustable wastegate, controlled either manually by the pilot or by an automated hydraulic or electrical system. When the aircraft is at low altitude the wastegate is generally completely open, venting all the exhaust gases overboard.

Rumored Buzz on Turbochargers

The elevation at which the wastegate fully closes and the engine still produces complete power is the crucial altitude. When the airplane climbs up above the important altitude, engine power output reduces as elevation boosts, just as it would in a naturally aspirated engine. With older supercharged airplane without Automatic Boost Control, the pilot needs to continually change the throttle to keep the required manifold pressure during climb or descent.